Markets & industries

Osela’s laser technologies power innovation across a wide range of markets and industries.

From life sciences, depth sensing to advanced manufacturing, our solutions deliver the precision, reliability, and performance needed for today’s most demanding applications.

Life Sciences

Specialized beam shaped laser illumination sources for bio-instrumentation Biological analysis using bio-instruments, for applications such as Drug development & DNA research requires the need for laser illumination sources as they play a key role in their working principle. Osela laser…

3D Machine Vision

Optimized illumination for 3D imaging applications 3D machine vision is a necessity in the world of Industrial inspection due to the requirement for efficiency improvement in manufacturing. There is a clear emphasis towards automation and quality control, which are both…

2D Illumination

Specialized illumination for 2D imaging applications Classic LED based illumination for 2D applications has its limitations at long working distances. Due to the high beam divergence of LEDs, the illumination brightness drops drastically as projection distance increase, resulting in poor…

Depth Sensing

Complex Structured Light patterns for 3D Depth Sensing Depth sensing is growing in importance within the world of industrial machine vision. Depth information helps solve and simplify challenging inspection tasks such as bin picking, gesture recognition, body scanning, volumetric measurement,…

Automotive Inspection

Osela lasers for 3D structured lighting is used in many stages of the Automotive manufacturing process. Single line lasers, multiple line lasers and random pattern projectors are chosen depending on the application requirements. Gap and Flush measurement is an example of…

Rail & Train Security

Osela laser pattern projectors perform varied tasks in the rail and train security industry. Monitoring, measuring and inspection is critical for rail transportation safety. Our Laser Line and Multiple line projectors are key components in performing machine vison and 3D…

Glass Manufacturing

Osela lasers are widely used in systems providing inspection and quality control solutions for the glass manufacturing industry. Osela’s laser pattern projectors are available in all wavelengths ranging from UV, Visible and IR spectrum.

Food & Beverage

Customizable Laser Pattern Projectors for Food Industry Applications Osela’s laser projectors, available in UV, visible, and IR wavelengths, enable precise machine vision solutions for the food industry—from product conformity checks to high-speed portioning and slicing systems—improving quality, efficiency, and reducing…

Bioinstrumentation

Osela’s laser platform with specialized pattern illuminations are very attractive for use as light sources in the Bioinstrumentation industry. Flow cytometers, for example, is an instrument used to identify and measure physical and chemical characteristics of cells as they travel…

Particle Analysis

Flows and sprays perform an important role in industrial, medical and environmental applications. Imaging these droplets and particles is fundamental to better understand and characterize the flow parameters.

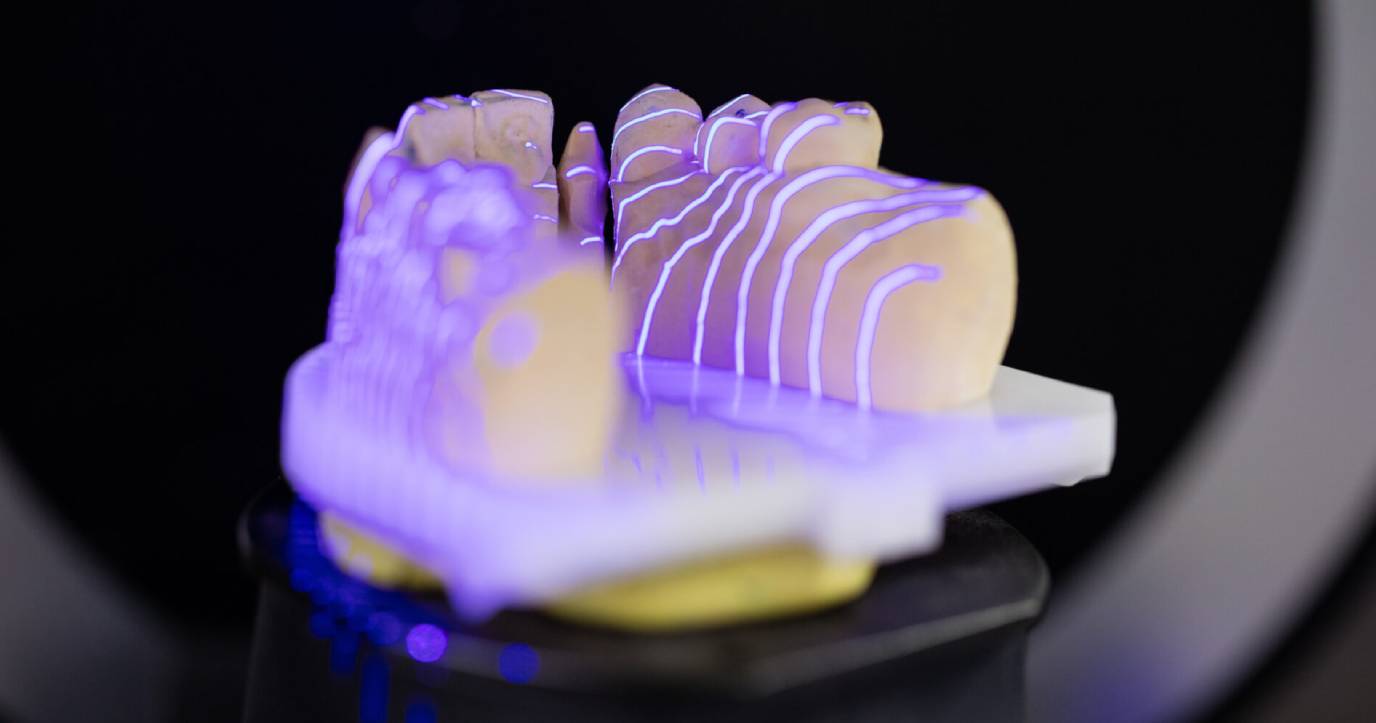

Dental Scanning

Laser imaging technologies are often used in dental laboratory scanners. The scanners are designed to create a 3D digital model of the dental mold or dental impression for crown and bridge manufacturing.

Cinema, Gaming & Entertainment

Pushing the Limits of 3D Capture for the Entertainment Industry 360° reality capture stages are now being deployed globally, powered by solutions like Osela’s Eye Safe Random Pattern Projector, to enable real-time textured 3D simulations of subjects.

Steel Inspection

High-Precision Inspection of hot steel beams with advanced laser systems In the intense environment of the forging process, ensuring structural integrity depends on the ability to clearly visualize hot steel components — a task made possible by high-power laser systems…

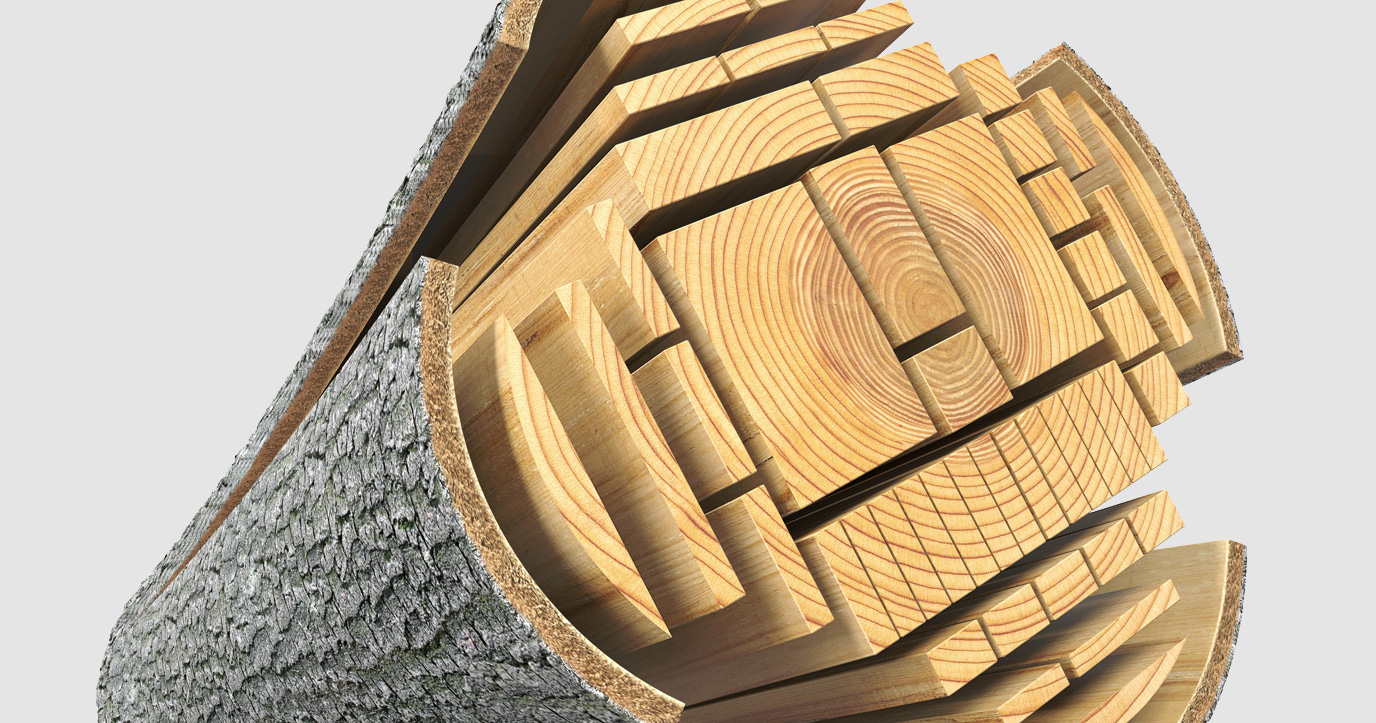

Lumber Processing

High-Uniformity Structured Light for Wood Optimization and Grading Designed for precision and scalability, our custom laser patterns — from multi-line to high-power dot arrays — deliver uniform Structured Light Illumination tailored to the demanding needs of wood processing systems.

Mining & Raw Material

Laser Innovation Driving Precision in Mining and Material Inspection From diamond grading to large-scale land surveys, advanced laser systems like structured light projectors and Time of Flight illuminators are reshaping how raw materials are analyzed and processed.

Security & Defense

Advanced Laser Beam Shaping for Security and Defense Applications Whether for biological threat detection or custom optical integration, our laser beam shaping expertise enables flexible, high-performance solutions tailored to the most complex defense system requirements.

Road & Infrastructure

Laser Illumination Solutions for Road and Transport Infrastructure From 3D surface profiling to high-speed 2D line scan imaging, our laser platforms — including Industrial Laser System, Fireline Laser, and Long Range Illuminator platforms — deliver high-contrast, reliable measurements even in…

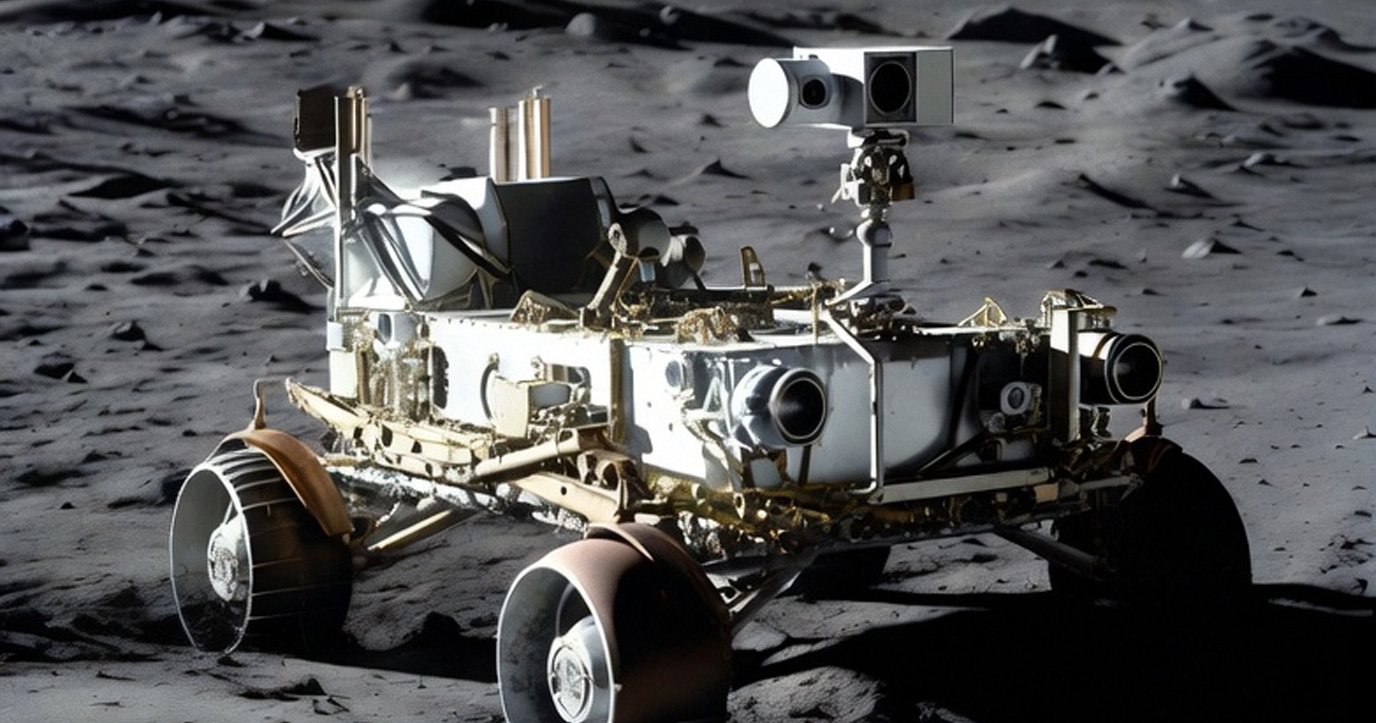

Scientific & R&D

Custom Laser Beam Shaping Solutions for Advanced Research and Innovation Leveraging our in-house expertise, we create tailored laser systems that empower groundbreaking projects—such as our collaboration with NASA to develop a structured light “virtual bumper” for Lunar Rover obstacle detection.

Pharmaceutical & Clinical

Specialized Laser Illumination for Pharmaceutical and Clinical Applications Commonly employed in pharmaceutical and clinical settings, laser projectors enable applications such as 3D inspection of capsule blister packs and fluorescence microscopy, while structured light systems enhance 3D body analysis and surgical…

Semi Conductors & Electronics

Precision Laser Illumination for Electronic Component Inspection Ensuring quality and reliability in electronic components requires constant verification of critical tolerances — a challenge met by Osela’s advanced 3D vision systems featuring uniform micron-focused laser lines and pattern projectors for enhanced…